SPEEDI®

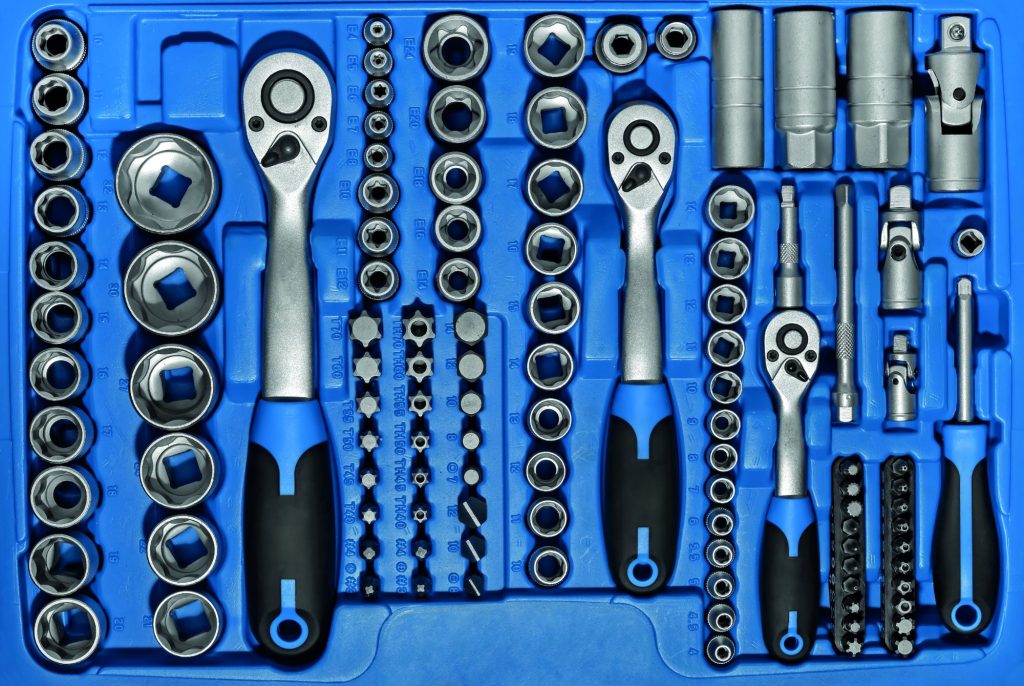

Smart toolbox for efficient and smart business processes in SAP

Where SAP ERP or S/4HANA reaches its limits because industry or process requirements become too specific, extensions help to work efficiently and transparently. SPEEDI offers a wide range of solution modules that can be seamlessly integrated into SAP and deployed quickly and easily.

Easily map numerous processes with SPEEDI solution modules

Regardless of whether your company operates in the automotive, electronics or manufacturing industries or in retail: In order to be successful on the market long-term - buzzword digital transformation - you need a high level of efficiency, flexibility, stability and transparency and end-to-end IT support in all of your business processes.

In the SAP environment, we offer you SPEEDI a powerful and investment-safe integration, solution and visualization platform. SPEEDI is seamlessly and release-compatible integrated into SAP ERP or SAP S/4HANA, complements and enhances the SAP standard in all areas (SD, MM, FI-CO, GTS) and maps even special process requirements with standard solutions in conformity with SAP.

With the elements from the SPEEDI toolbox, you are able to individually configure, parameterize and automate order, release performance, delivery, or credit memo processes quickly and easily via customizing. This is an immense advantage because it allows you to implement variations of processes as well as new processes quickly and without additional programming.

Advantages

As a "smart toolbox", SPEEDI provides you with numerous configurable and reusable functions "out of the box" - monitors, reports, solutions and forms - for very specific process requirements that integrate seamlessly with SAP ERP. There are currently more than 1,400 of these components, and new ones are being added continuously. SPEEDI "out of the box", numerous configurable and reusable functions - monitors, reports, solutions and forms - are available for very specific process requirements that integrate seamlessly with SAP ERP. There are currently more than 1,400 such modules, and new ones are being added all the time.

Solutions for efficient OEM processes in SAP

As an automotive supplier, you will benefit above all from the in SPEEDI stored OEM solutions. They map the EDI-based logistics processes of numerous automotive manufacturers (OEM), for example the "New Logistics Concept" (NLK) of Volkswagen, including all forms consistently in SAP ERP. WSW Software also provides the required mappings.

Bundle up and visualize process data on one interface

In all this bundles and visualizes SPEEDI process-relevant information organized on a single interface, where you can seamlessly monitor processes and data, immediately detect errors or problems, and take the necessary measures without delay.

Investments pay off quickly

Since SPEEDI is always installed as a complete package, process enhancements and solutions are immediately ready for use and can be utilized, so that your investment in the add-on pays off quickly. The fact that we at WSW Software support the implementation with our entire consulting and process expertise and comprehensive services also makes a significant contribution.

Future-proof SAP-based add-ons

To ensure that you continue to receive the greatest possible business advantage from SPEEDI in the future, the add-on is optimised for operation on the SAP HANA database and on the new ERP suite SAP S/4HANA.

Individual solutions

The following SPEEDI tools "Replenishment control" and "Daimler RFID" are examples of how diverse the SPEEDI toolbox is.

An excerpt of our customers

Director Business Unit SAP & Digital Supply Chain

T: +49 89 895089 426

M: wolfgang.salinger@wsw.de