A factory that organizes itself and produces autonomously. - Dreams of the future? Not necessarily. However, to realize such a production environment, a number of cutting-edge technologies must be combined in a targeted manner. If this succeeds, considerable competitive advantages will result.

What is a Smart Factory?

The Smart Factory is an intelligent factory and refers to an innovative production environment that organizes and optimizes itself with the help of various technologies. Ideally, human intervention is no longer required in this factory of the future, because production facilities and logistics systems are fully automated.

What are the technical requirements for a smart factory?

Cyber-physical systems (CPS) play a central role in the smart factory. These are IT systems in which mechanical components are interconnected via information technology and networks. With the help of CPS, it is therefore possible to implement intelligent networking of machines, products and logistics. The networked product shares all production-relevant information with the smart factory. Based on this data, the entire production process controls itself.

In addition to cyber-physical systems, complementary technologies play an important role in smart factories:

- Internet of Things (IoT) and digital twin

- Communication Technology

- Big Data Technologies

- Cloud computing

- Systems for controlling and monitoring networked objects (embedded systems)

- Robotics

- Intelligent logistics systems

- Artificial Intelligence (AI)

- Factory control platforms

Internet of Things (IoT) & digital twin

To implement a smart factory, it must be virtually mapped with all its components. For this purpose, all machines, products and other components such as tools or transport systems are given a so-called digital twin - in other words, a virtual image. In order for the digital twin to reflect the current state of its physical counterpart, it needs to be supplied with real-time data. This data is collected by sensors and made available via the Industrial Internet of Things (IIOT).

Products and machines that are networked via IoT can not only send data, but also receive commands. It is therefore also possible to control production plants via the IoT. The commands are executed via so-called actuators.

Communication Technologies

In order to realize communication between products, machines and higher-level control systems, the smart factory requires suitable communication technologies. These can be wired or wireless. From today's perspective, the following communication technologies are possible:

- LAN

- WLAN

- Bluetooth

- RFID

- NFC

- UWB

- ZigBee

- 5G

When selecting a transmission technology, reliability (fail-safety), performance, communication security, environmental conditions and the specific application play a role above all.

Big Data Technologies

The comprehensive networking of machines and products in a smart factory generates huge amounts of data (big data). The situation is further complicated by the fact that the data can be in a variety of formats and also unstructured. These can no longer be processed and evaluated using conventional methods. Instead, modern Big Data technologies are required for this purpose. These include, above all, special data storage and databases that enable very high-performance processing and analysis of large volumes of data.

Cloud computing

Another important technology for the smart factory is cloud computing. For many companies, it is uneconomical and technically too complex to store and process the large volumes of data for a smart factory locally. It is more effective to outsource the data to external data centers of specialized service providers. IoT platforms and the control and monitoring systems of smart factories can also be operated there. A key advantage of cloud solutions is their scalability. Thanks to this feature, unlike local systems, they can easily grow along with increasing data volumes.

Systems for controlling and monitoring the networked objects

(Embedded Systems)

Embedded systems are computers, microchips or control units that are embedded in numerous smart factory objects - such as machines or robot arms. Among other things, they enable a connection to be established to the object. Their two core tasks are the collection and independent processing of data. This makes them an important technology in terms of remote control and automation.

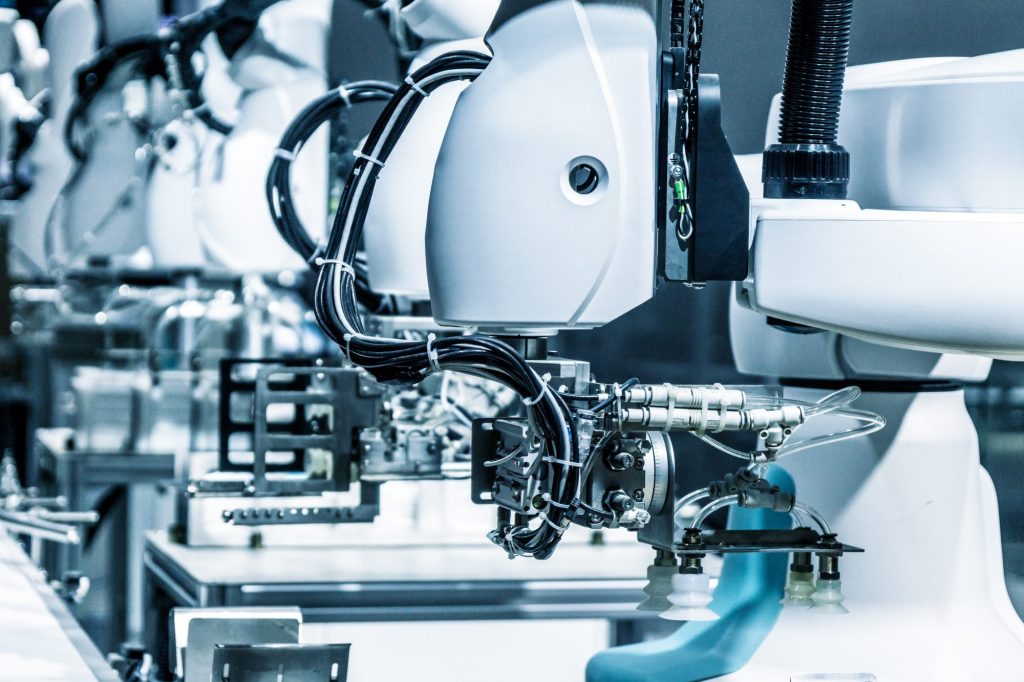

Robotics

Robots are not a novelty in industry per se. They are already contributing to the automation of production. They also support intralogistics. In the factory of the future, however, industrial robots will be able to act even more autonomously and flexibly with the help of artificial intelligence.

Intelligent logistics systems

In a smart factory, not only manufacturing must be automated, but also material supply. This requires modern, networked and autonomously acting logistics systems. In addition to logistics robots that pack, label, palletize or pick, these include driverless transport systems (AGVs). Prerequisites for the functionality of such systems are suitable technologies for the communication, location and identification of materials, intermediate products and products.

Artificial Intelligence (AI)

Artificial intelligence (AI) can be used in the smart factory in several ways. For example, it is capable of predicting the failure of machines with the help of Big Data and requesting maintenance measures in good time. Furthermore, it can be assumed that AI will be able to take over the following tasks in the future:

- The implementation of quality controls (detection of defects)

- The forecast of the supply and demand situation with corresponding adjustment of the production planning

- The support of robots and logistics systems

- The recognition of improvement potentials, self-optimization of production and logistics

Factory control platforms

In order to automate and monitor the processes of an intelligent factory and to be able to intervene manually if necessary, suitable planning and control systems are required. From today's perspective, these are primarily two types of software:

- The ERP system: This is responsible for networking production with the business level (e.g. receipt of customer orders, material procurement from suppliers, warehouse management).

- The Manufacturing Execution System: It handles planning and control of production, receives orders, schedules resources, reports progress, orchestrates quality controls, and establishes traceability.

Application examples for a Smart Factory

The idea of the smart factory is being pursued in the automotive industry, among others. Audi, for example, already started up a "smart factory" in Mexico in 2016. The Q5 model is manufactured here, with only around 100 employees. They are primarily responsible for monitoring the production processes from the control station. At other Audi sites, production employees are supported by technologies such as Big Data, augmented reality and artificial intelligence. The carmaker is also working on the use of new automated transport systems that orient themselves independently with the help of lasers.

This example and projects in other industries show: The fully autonomous smart factory is still a vision of the future. However, the relevant components are being implemented step by step. In this way, companies are gradually approaching the final expansion stage of the smart factory.

What are the advantages of a Smart Factory?

A smart factory brings numerous benefits for companies. In particular, minimized production costs and an optimization of processes are worth mentioning. Thanks to intelligent networking and self-organization, smart factories are also able to model manufacturing processes very individually and flexibly. This makes it possible to produce small batches and individual products ("batch size 1") within a cost framework that can only be achieved in traditional factories by means of mass production.

In addition, the Smart Factory has the following advantages:

- Shorter, more stable and predictable production times

- higher delivery reliability

- higher and consistent product quality

- lower costs of warehousing

- optimized procurement processes

- lower personnel requirements

- Accelerated implementation of innovations

- Fast adaptation to changing conditions

- Higher productivity, efficiency and effectiveness

- Reduced downtime and idle time

The extent to which companies are already developing in the direction of Smart Factory and Industrie 4.0 can be discussed using the Industrie 4.0 Maturity Index. The Industrie 4.0 Maturity Index is a six-stage maturity model. It analyzes important capabilities of companies that are urgently needed for digitally networked processes. These include, for example, aspects of the cultural and organizational structure or information systems.

Conclusion

Overall, it is clear that companies can benefit significantly from the digitization, networking and automation of their production. However, the path to the smart factory in the final stage of development is still associated with a number of technological hurdles. For example, modern technologies such as connectivity solutions, IoT platforms and Big Data applications must be tested and implemented step by step in order to move closer to the goal. This, in turn, requires investment as well as fundamental cultural and structural change within the company. Nevertheless, manufacturing companies must not close their minds to this development, as this could mean losing competitiveness in the medium term.

FAQ

We explain the most important terms in the context of the Smart Factory here:

A smart factory is a production environment that organizes itself. Manufacturing plants and logistics systems are automated to the maximum. All plants and products are networked. Processes are controlled and monitored using software (AI and Big Data applications).

A smart factory can significantly reduce production costs. At the same time, it is possible to respond faster and more flexibly to customer requirements. In addition, product quality can be increased by eliminating human error.

The realization of a smart factory is associated with enormous technological challenges. All production and logistics systems must be seamlessly networked and able to exchange data with each other in real time. This requires high investments and is a time-intensive undertaking.