Sequencing

The supreme discipline of Just in Sequence (JIS) processing

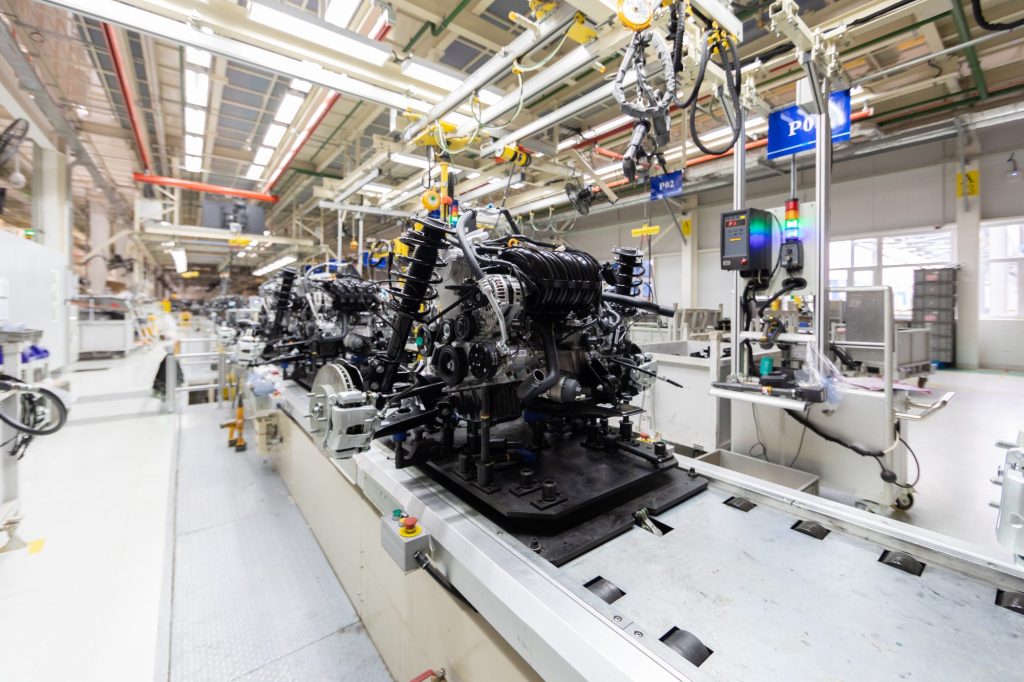

As a supplier or logistics service provider, you know that with Just in Sequence (JIS), smooth production on the part of your customer depends to a large extent on your correct delivery. From the EDI-supported JIS call-off from the customer to the sequence-correct delivery of the components to the assembly line, you often only have a few hours, sometimes less than 30 minutes.

Fast and smooth JIS processing

Fast, precise, and smooth JIS processing is thus a competitive factor in which every detail must be carefully considered from the very beginning. The order in which the ordered components are produced, picked, filled into containers and loaded onto trucks is determined on the basis of the customer's sequence specifications.

In doing so, it is always necessary to take sequence shifts on the part of the customer into account or to integrate special productions into an ongoing production sequence. A high degree of flexibility is therefore an important success factor.

JIS peculiarities in the automotive industry

For suppliers in the automotive industry, it is also imperative to master manufacturer-specific processes and special procedures and to map them in a practice-oriented manner: be it the AUDI bead chain, the BMW SPAB procedure including tachometer control, the New Logistics Concept (NLK) from Volkswagen or variant mapping via VCCBOM from Volvo.

Often, different plants of one and the same manufacturer also have completely different requirements for JIS processing. And if you are an international supplier, electronic communication with foreign customers often has to take place in special EDI formats - in the USA, for example, via the ANSI X12 standard, in Brazil via ANFAVEA RND message.

Efficiently mastering increasing JIS complexity

As if that were not enough, the complexity of sequencing processes is constantly increasing due to ever new product variants. In order to master the associated challenges in the long term and with the greatest possible effectiveness, you need a future-oriented JIS concept and a JIS solution tailored to your needs.

Because JIS projects are extremely complex, it is advisable to involve a competent partner like WSW Software. We support you with concentrated JIS know-how in terms of conception, solution selection and implementation as well as in ongoing operation with consulting, programming and support around the clock (24/7).

Our process solutions

In order to supply production at the customer's site on time and in the correct sequence at all times, suppliers, logistics and sequencing service providers need a modern, powerful, flexibly configurable and highly available JIS and logistics solution as the central clock for their JIS processes.

LOJISTIX

LOJISTIX SAP JIS INTEGRATION PACKAGE

SPEEDI SAP JIS

If you want to map JIS processes yourself, you need digital support. There are various solutions for this. The advantages and disadvantages of these alternatives cannot be generalized. Apply to any situation. It strongly depends on the functions of the specific software solution, on the requirements of the customers to be supplied, on the number of customers and also on the existing systems.

We compare the five most important solutions.

FAQ

The most frequently asked questions about sequencing

The term sequencing refers to the creation of a specific sequence. In the automotive industry, this is understood to mean the delivery of parts to match the production sequence of the vehicles at the OEM. The supply concept is called just-in-sequence and extends just-in-time (the right quantity, at the right time, at the right place) to include the right sequence.

Basically, just-in-sequence refers to the type of delivery. However, there is a lot of variety under this umbrella. For communication, for example, different message standards (VDA, EDIFACT, ANSI-X12, XML, web portals) are used. Furthermore, each OEM has its own special logistical requirements, which are mapped in the messages.

Incorrect deliveries have serious consequences at JIS and you are obliged to deliver in the assembly sequence of the vehicles. One wrong part can even lead to a line stoppage at the car manufacturer. In addition, this type of delivery may be very short timed. Sometimes only a few hours pass between receipt of the order via EDI and installation in the vehicle. At JIS, you need software that ensures the correct sequence right up to packaging in the container and that can best meet the requirements of all OEMs.

Director Business Unit SAP & Digital Supply Chain

T: +49 89 895089 426

M: wolfgang.salinger@wsw.de